Blueflame Energy Solution Ltd, based in Nairobi, Kenya, is a leading provider of wastewater and sewage treatment systems. We design, install, operate, and maintain treatment plants across residential, commercial, institutional, municipal, and industrial sectors. Our systems comply with the Ministry of Water and Irrigation standards, Environmental Impact Assessment (EIA) requirements, and NEMA guidelines.

We specialize in: – Sewage Treatment Plants (STP) – Effluent Treatment Plants (ETP) – Industrial Wastewater Treatment Systems – Compact Plug-and-Play Systems – After-sale support, spare parts, and maintenance

Our goal is simple: Treat. Reuse. Comply.The Blueflame waste water treatment plant is a domestic and commercial system that offers an extremely efficient and unobtrusive means of sewage management disposal. The Biodigester is a three-stage wastewater treatment plant. The bioreactor incorporates unique features to ensure simplicity and efficiency of operation. It meets the standard of environmental impact assessment (E.I.A), a requirement for all construction projects.

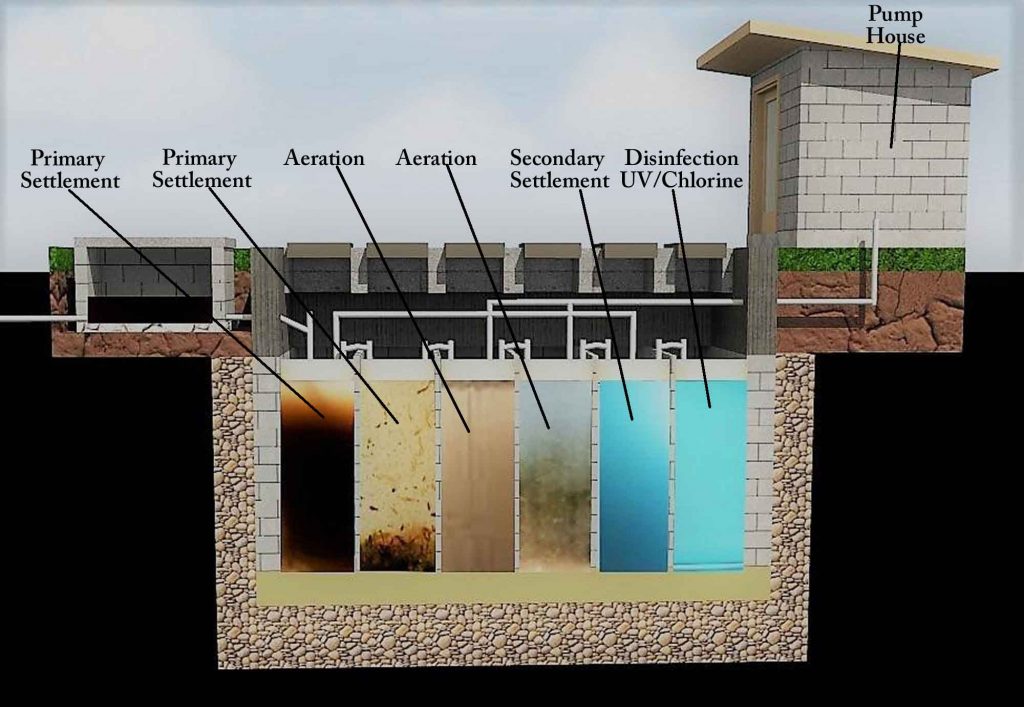

WATER TREATMENT PROCESS (General Flow)

Sewage from washrooms → Pretreatment & Screening → Anaerobic Digestion → Equalization → Bioreactor (SBR/MBR) → Clarification → Disinfection (Chlorine/UV) → Clean Water Storage Tank. Parameters monitored: pH, Color, Turbidity, BOD, COD, TOC, TSS, TN, TP, and coliform counts.

Available in a range of sizes.

We are flexible to construct any size from 4000 liters depending on the population. This wastewater treatment plant is designed to replace the old septic system by holistically providing the following client and environmental advantages.

- It’s eco-friendly.

- It does not require frequent exhaustion and drainage.

- Its effluent is clean water that can be recyclable to the environment i.e. cleaning, to the stormwater drainage, to the streams, rivers or use in the garden.

- It can fit any available space from 2m sq.

- No need for separating water from the toilet and bathroom and kitchen

- It can run on both 3 phase and 2 phase.

- Very low electric consumption

- Very clean effluent giving 11mg/liter BOD and 7mg/L Ammoniacal Nitrogen

- Very Quiet operation

- Gravity and pumped outlet options

- Alarms are standard

- 5-year tank warranty

- Can be designed to be installed above ground if required

- It can be designed to be MOBILE wastewater treatment systems for disaster areas, temporary construction sites, etc.

- Can be made to suit any drain depth

- Sludge Return facility enables holiday absences and denitrification

OUR MODELS

ASBR (BZM FIX MODEL)

The ASBR wastewater treatment system is an advanced waste water purification technology designed to deliver effective sewage treatment for large communities. The process provides

for full Carbon and Nitrogen removal to produce high quality effluent that is odour free, suitable for reuse such as in irrigation.

SBR (BZM MODEL)

The SBR wastewater treatment plants use the Sequential Batch Reactor process to provide effective treatment of sewage water in various applications in scale from residential to large communities. The SBR process provides for full Carbon and Nitrogen removal and produces high quality effluent that is odor free and suitable for re-use including irrigation and toilet flushing. Due to its high quality it may also be discharged into sensitive water courses.

SBR systems use in-ground site constructed concrete chambers with ancillary equipment including aerators and pumps centrally installed and controlled in an adjacent machinery housing room.

Sequencing batch reactors or SBRs use a separate pre-treatment section to mechanically hold back solids and a biological aeration and settling tank.

BZM/SBR SYSTEM OVERVIEW

Primary Screening: Removal of indigestible materials.

Primary Settlement: Anaerobic digestion and sludge reduction.

Equalization: Balances peak flows.

Aeration: Biological oxidation via aerobic digestion.

Secondary Clarification: Settling of treated effluent.

Disinfection: Chlorination or UV treatment.

Desludging: Sludge returned to primary treatment.